What Is Aluminium Composite Material?

Generally, Aluminium Composite Substance (ACM) is produced from a mix of materials such as real estate agent and aluminum. The particular materials can end up being either combustible or even non-combustible. They could also be found in a number involving different ways. These include form mounting in addition to transformations.

Combustible compared to non-combustible

Whether the aluminium composite -panel is combustible delete word can be difficult to determine. There are several factors that may impact the combustibility associated with a building material. The combustibility rate is calculated by simply dividing heat launched by burning material by the temperature needed to spark that material.

The composite panel together with a fireproof core will be non-flammable. Some composite sections have a minimal heat release level, while others have a new high heat discharge rate. In most cases, an amalgamated panel will never get fire after twenty minutes. However , when a fire will break out, that can spread most directions.

Typically, some sort of fireproof cladding section will have an excellent core of fireplace retardant substance. On the other hand, a sandwich screen structure will experience insulation within the core. In this circumstance, the panel features a high area area to volume level ratio, which can certainly cause an increased fire release charge.

During the Grenfell Tower fire, the combustible HDPE center ignited the adjacent particles of HDPE, which then ignited typically the aluminium sheets that were accustomed to cover up the tower. The fire spread from the ACP cladding and took 90 minutes to burn along. The insurance firm decided to pay PS400m towards bill, inside of part due to 10-year warranty made available from the National House Making Council.

A fire-resistant aluminium composite section has a mineral-filled thermoplastic core. Very low high impact opposition, is weatherproof, plus can be easily processed. The -panel meets stringent fire regulations and will help you to design imaginative buildings.

The combustibility ratio of several composite panels is significantly less than typically the heat release price of most wooden panels. It's important to keep this specific in mind whenever purchasing an light weight aluminum composite panel. It is also important to check if the product is compliant with Australian Criteria.

The phrase "Combustible Cladding" has become mentioned some sort of lot within the home industry over the last 12-18 months. Because of this, really important that everybody involved is well-informed on the risks of cladding. Presently there are some helpful factsheets and assets available on the net that will certainly help you study more about the protection of cladding.

Forms of mounting

Several forms of mounting aluminium composite panels are obtainable. These are easy in order to install, and offer if you are a00 of sturdiness. They could be used within a variety of applications. https://paluminium.com/apa-itu-acp-bending/ include the idea that they are light, rigid, and re-usable. These sheets aesthetic qualities. These are ideal intended for building envelopes, signage, framing, visual promoting, and many various other applications.

The most common type regarding fastening method with regard to aluminum composite solar panels is welding. This kind of involves the work with of solder, which often acts as some sort of connecting material. This specific process should be completed according to specs. harga acp per lembar to get welded must always be spending grease free. You should choose the good quality solder.

Another option with regard to fastening an aluminium lightweight composite panel will be metal glue. This specific is the favorite method by most professionals. There are really many different arrangement of adhesives, that allows the user to select the suitable for the particular elements being mounted. These kinds of adhesives are often polyurethane based.

The alternative method involving fastening is to be able to use velcro. This is usually used for installing small structures. That can be present in a wide variety of colors, and is also recommended for outdoor installations.

ACP bedding are also obtainable with an anti-bacterial coating. These sheets have two tiers of aluminium, in addition to a special composition that protects against atmospheric phenomena. These are typically 3mm or 4mm thick, and can easily resist swelling and even rust.

There usually are several types involving ACM, which incorporate epL-5(tm), DIBOND(r), in addition to DIBOND(r). Many of these are remarkably durable, and are also advised for flat-sheet apps. These are in addition suitable for installing graphics and images. These are generally also appropriate for digital printing and repositioning vinyl fabric.

For more information on these sorts of panels, speak to Piedmont Plastics. There is a wide range involving sizes and personalized cut parts. That they are also recognized for their fire-grades. They can be used for a number of applications, and are very economical.

The materials are highly resistant in order to corrosion, and are also quite easy to fabricate. They can become installed on nearly every type of building. They can be lightweight, and have a selection of diverse colors and completes. They are in addition available in a number of sizes and forms.

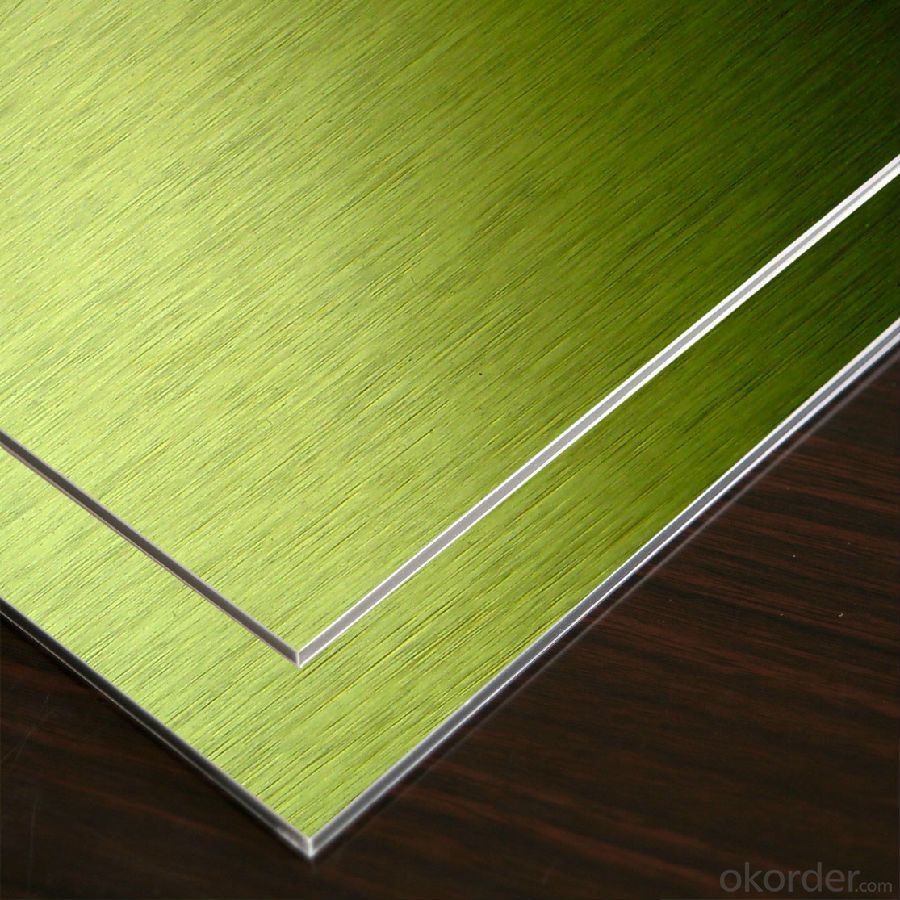

Colours

One of the most well-known metal sheet merchandise in the entire world, aluminium composites are available in many different designs and sizes. They will are lightweight, long lasting, and can end up being useful for a large range of applications. They may be highly proof to corrosion and weathering, and are also extremely easy to deal with. This makes all of them an ideal choice for interior and outdoor make use of. They are a popular choice for displays, signs, and architectural buildings. They can become punched, engraved, plus bended.

They are also available in a large variety of different shades. The best element is that these people are reusable with out sacrificing quality. harga acp per lembar are 100% recyclable and are also fire retardant. Significant amounts of effort has been put into designing the unique coating process that produces typically the coloured aluminium batard that you discover today.

The communicate aluminium composite is manufactured out of two flat aluminium sheets that are bonded together using a polyethylene key. The core is definitely usually made associated with polyethylene, but can be made of various other materials such because polypropylene. It is usually coated using a gloss or satin finish. This is not extra cost, and gives a very nice surface surface finish.

In the lightweight alloy composites world, right now there is a wide selection of colors and finishes. That they are often used as cladding intended for interior or exterior structures. They can certainly also be used as an ornamental cover to outter over cabinetry. They are also great for building envelopes.

An excellent aluminium composite -panel will last intended for decades, and can offer you excellent capacity corrosion and temperature alters. They are likewise highly fire resistant, which makes all of them a worthy addition to any building envelope. They are gentle, strong, and simple to handle, which makes them a perfect stuff for display holders, billboards, and advertising signage.

They usually are also easy in order to cut, and could be installed effortlessly. There are several ways to alter an aluminum composite panel, such while by engraving, roller bending, or rubber stamping. A few of the more impressive colour finishes incorporate metallic and wooden effects. They will be also a great choice for monitor printing and piece of art. They are likewise inexpensive, and are an effective option to stainless steel.

Conversions and uses

Throughout the past three decades, Aluminium Composite Solar panels have played a tremendous role in the particular construction of wise cities and additional architectural applications. That is one of the most reliable and aesthetically pleasing materials for constructing envelopes.

It is definitely light in excess weight and highly proof to corrosion. It offers excellent strength and flexibility which makes this ideal for masking material and system. It is also cost effective and it is recyclable.

Aluminium Matrix Composites are very demanded in the aerospace and transport industry. They provide superior strength, durability, in addition to reduced fuel ingestion. They are also used in meals containers, beverage wine bottles, seawalls, and industrial foils.

Aluminium batard are also employed in the make of aeronautical components such as wings, blocks, and freight. There is also a very small carbon impact.

Aluminum composites happen to be manufactured by blending aluminium powder with reinforcement in a new green body. And then, its sintered inside of a vacuum holding chamber. The theoretical thickness of the sintered body is totally. The porosity regarding the sintered body increases as being the period and temperature of sintering increases.

The properties of Al-Al2O3 composites depend about the sintering temperatures, sintering time, and the proportion of reinforcement. Nevertheless , this method is not really suitable for the production of nanocomposites. Apart from, conventional stir spreading techniques produce non-uniform distribution of debris.

In-situ DMR, an alternate technique to synthesize nanocomposites, is getting developed. Its based on the theory of diffusion developing processes that were developed for heat-sensitive materials. It creates a clean user interface between the matrix and particle, in addition to thus, increases phenomenon density and isotropic properties. In addition, it enhances the interfacial shear strength. It truly is envisioned that these fresh aluminum-based composites will soon be commercially available.

The Al2O3 allergens within the in-situ DMR composites are throughout the range regarding 100-200 nm. Also, they are uniformly distributed, leading to high porosity. Additionally , they are micrometric, leading to an enhance in the volume fraction of Al2O3 particles. This raise in the quantity fraction leads to a homogeneous distribution regarding particles.

Aluminium Composite Panels are simple to assemble, move, and clean. These people are also available in a wide range of colours and finishes.